All responsibilities concerning scheduling were allocated to a single employee. This meant that one man was responsible for keeping production up and running at all times, for ensuring that the required orders were produced and for ensuring that produced goods were delivered on time. This is a heavy burden for any one man to bear. We really needed help, and we chose ROB-EX as our solution to solving the problems.”

EME Hydraulic: An important step toward digitization

ROB-EX was meant to solve our scheduling challenges, provide us with an overview of all orders and contribute to a calmer working day. Today I will say we can’t do without it. It is so important for our customer relations that we are able to say when we will deliver. We can trust the system and avoid inventing things on the hoof. The constant state of alarm we experienced before has by and large vanished with ROB-EX.

Maskinfabrikken Silkeborg Spåntagning: We now have a better understanding all way round, as everyone is kept up to speed

With ROB-EX, we have really gained a full overview of production, and it’s simply great. Especially since we set up viewers in production, so that everyone can see what’s going. Virtually everyone in the company uses ROB-EX – even our owner and CPO.

Knudsen Extrusion: Now we can deliver an order confirmation in 5 minutes

With ROB-EX the planning process at Knudsen Extrusion has become easier, faster and with less friction. It used to be a cumbersome work to process a customer order because the consequences had to be calculated in Excel. Now the planning staff can execute quick and precise analyses in ROB-EX so that the customer can get an almost immediate response.

East Metal: 10% increased efficiency with a new tool for production planning

The great visibility that ROB-EX provides has improved our efficiency with nearly 10%. We now have a 89% utilisation rate of the man-hours available and this has immediate effect on the bottom line.

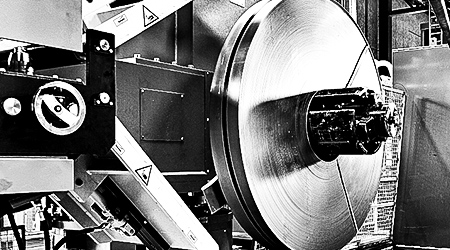

Ib Andresen Industri: Introducing ROB-EX in production is like introducing a GPS in your car

“ROB-EX is the heart of the production plan in the roll forming department at Ib Andresen. It is now an indispensable management tool in our production scheduling”, says René T. Skov – Planner in the Roll Forming Department.

JP Group: Resource management with ROB-EX in complex production

Rynkeby Machine Shop have more orders in production and their delivery performance is improved

Before the investment in ROB-EX, Rynkeby Machine Shop had another scheduling system that did not work properly.

OTV Plast handles more orders because of better scheduling

Henrik Jylov, Managing Director at OTV Plast, states: “In the first three years with ROB-EX our orders have tripled without an increase in our number of employees. I give ROB-EX a significant part of the credit for this”.

Delivery on time gives customers a better service at Krogsgaard’s Machine Shop

Krogsgaard’s Machine Shop uses ROB-EX to schedule their entire production, thus ensuring that products reach the customers on time. Compliance with delivery dates are improved significantly and are generally kept for every order.

- Page 1 of 2

- 1

- 2