With ROB-EX the planning process at Knudsen Extrusion has become easier, faster and with less friction. It used to be a cumbersome work to process a customer order because the consequences had to be calculated in Excel. Now the planning staff can execute quick and precise analyses in ROB-EX so that the customer can get an almost immediate response.

East Metal: 10% increased efficiency with a new tool for production planning

The great visibility that ROB-EX provides has improved our efficiency with nearly 10%. We now have a 89% utilisation rate of the man-hours available and this has immediate effect on the bottom line.

WOCA has increased production by 20% – same manpower

”Without ROB-EX, WOCA Denmark would not have improved efficiency to the extent that we have – and certainly not as rapidly. WOCA has been able to shut down the nightshift, thanks to ROB-EX – and we have increased day-time production by 20% – without additional manpower”

De Danske Gaerfabrikker (”the Danish Yeast Factories”) increased production capacity by 15-20% with ROB-EX

We have increased capacity and improved efficiency significantly by implementing ROB-EX – and we expect to continue to do so. I would like to commend ROB-EX for the way that the system pinpoints the areas in production that have capacity to yield more output.

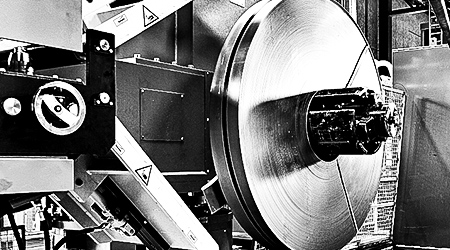

Ib Andresen Industri: Introducing ROB-EX in production is like introducing a GPS in your car

“ROB-EX is the heart of the production plan in the roll forming department at Ib Andresen. It is now an indispensable management tool in our production scheduling”, says René T. Skov – Planner in the Roll Forming Department.

JP Group: Resource management with ROB-EX in complex production

Rynkeby Machine Shop have more orders in production and their delivery performance is improved

Before the investment in ROB-EX, Rynkeby Machine Shop had another scheduling system that did not work properly.

Bifodan has improved their on-time delivery rate from 82% to 98% and have increased their turnover

ROB-EX provides overview of the production processes of Bifodan, ensuring that production is scheduled so that resources and materials are utilised optimally.