Resource Transition Rules will add more detailed constraint modeling, down to single-resource and single-product. The transition rules enable the possibility to block resource changes depending on the previous or next operations (i.e. not only based on the current operation, but also where it comes from and is going to).

Transition rules also allow us to reserve extra equipment between operations in a route depending on which resource the operation is allocated to.

The ordering of the rules matter. When evaluating the rules, less constraining rules will not be considered if there were a match with a previous, more constraining, rule. E.g. if there is a rule in the list with a product and that product matches the source operation, then this rule is more constraining than rules without a product, so if we encounter rules further down the list, that does not have a product that matches the source operation, then these rules will be skipped.

Apply transition rules when the physical equipment has limitations. In the process industry, it is very typical where liquid is pumped between tanks using physical pipe connections.

Example1: The size or complexity of a product limits an order to selected resources only

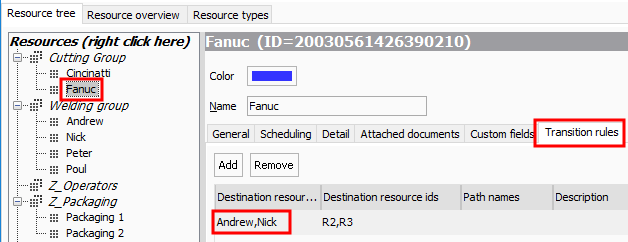

In the following example Fanuc handles cutting of very large and complex products. Only two welding operators are qualified for handling products from Fanuc, so it is only possible to go from “Fanuc” to “Andrew” or “Nick” (Peter and Poul are not allowed).

The transition rules are checked both ways, so if the welding operation is currently on Peter or Poul, Fanuc cannot be selected for the cutting operation.

Example 2: A pipe transfer line is needed when transferring the product between two tanks.

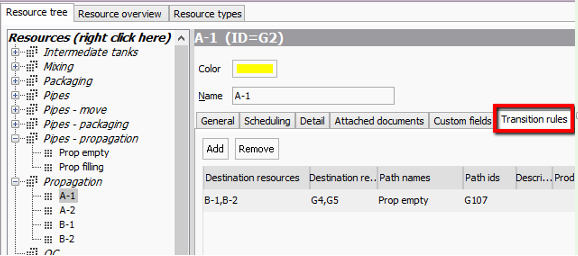

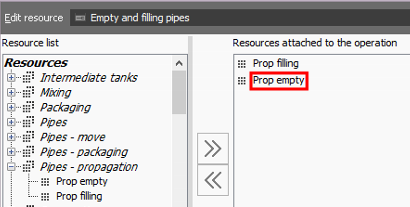

In the following example it is only possible to go from A-1 to B-1 and B-2 by using the pipe transfer line called Prop empty. So enter the name Prop empty in the “Path” setting.

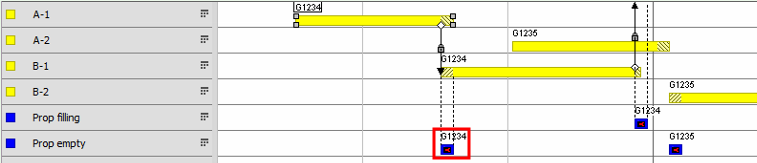

When an operation in order G1234 goes from A-1 to B-1, then the equipment Prop empty is used, visualized as a sub-operation in below example. The sub-operation is automatically created and removed as needed.

A master sub-operation must exist with the possible equipment configured. Create additional sub-operations in Edit->Operation. The sub-operation also determine on which time step the sub-operation is connected to the primary operation (setup, workload, etc.). In above example the time step connects to the Emptying time.

Configuration possibilities.

Setting a specific step for the added sub-operation. Of course this can be set on the template sub operation, but then all paths to a resource share the same link step. The sub-operation link step can also be specified in the path to override the template sub-operation step association.

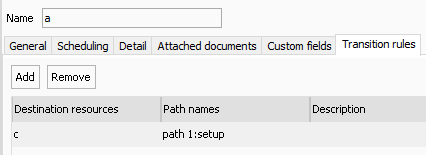

In the example the resource “a” has a transition rule with the path “path 1:setup” and the resource b has “path 1:workload”.

The transition from a to c results in a sub-operation on setup and the transition from b to c results in a sub operation on workload.

The step options are: PRE_QUEUE, SETUP, FILLUP, WORKLOAD, EMPTYING, SWITCHOVER, MAX_STORAGE, POST_QUEUE, and TRANSPORT. the names of the steps are case insensitive.

Post your comment on this topic.