The short answer is: Yes! Your choice of business management systems is pivotal to company operations. Best-of-breed software is specifically dedicated to one clearly defined company function, and is developed by specialists with specific expertise in that particular field. All-in-one solutions aim at facilitating most – if not all – functions and activities within the framework of one system. It often seems convenient and less complicated to have one system for managing everything. Not only does it seem simpler, it also stands to reason that one comprehensive system is cheaper than buying several specialised solutions. Everything is put into one system and you only need to pay one subscription. But is it really correct that you benefit more and save money by going for an all-in-one solution?

At ROB-EX A/S, Sales Director, Kristian Skytt Mikkelsen is in no doubt: ”With all-in-one solutions, all the company’s activities and functions are collected in a single system. This is great for certain things. However, we challenge the idea that one comprehensive system is equally strong and specialised in relation to all activities and functions in a company. All-in-one solutions manage everything from finances, stocks, customers, sales and production scheduling. We haven’t yet seen an all-in-one solution that covered each of these functions equally well. Some areas are simply too complex to manage in a generic solution that is designed as a one-size-fits-all system. Usually, these systems are based on one key area, e.g. finances or customers, and then the core system is rolled out and forms the basis for the other areas as well. In some cases, the generic framework actually compromises the efficiency of other company functions. We often see this in relation to production management and scheduling.”

Most enterprises benefit greatly from implementing all-in-one solutions and combining them with best-of-breed solutions for specialised areas. The trick is to know the areas in which one or the other solution will generate the most value.

”Best-of-breed should be viewed as ’the best specialised tool’ for a certain function. Best-of-breed software is developed for the specific purpose of supporting enterprises in performing optimally in a particular area. One of the areas that’s most obviously well-suited for best-of-breed software is production scheduling. It’s a highly specialised area that involves juggling with all of the company’s most valuable resources: machinery, materials and employees. The most efficient allocation of all of these resources requires a tool that’s dedicated and designed specifically for managing the particular challenges related to scheduling, and a tool that offers features and functionality specifically aimed at strengthening and improving this particular area. Even minor improvement, for example in efficiency, may significantly improve the bottom line. Scheduling is an area that directly involves the company’s assets and resources on a daily basis, and leaving this area within the generic framework of an all-in-one solution is nothing short of a gamble,” says Kristian Skytt Mikkelsen.

Loss of overview equals loss of profits

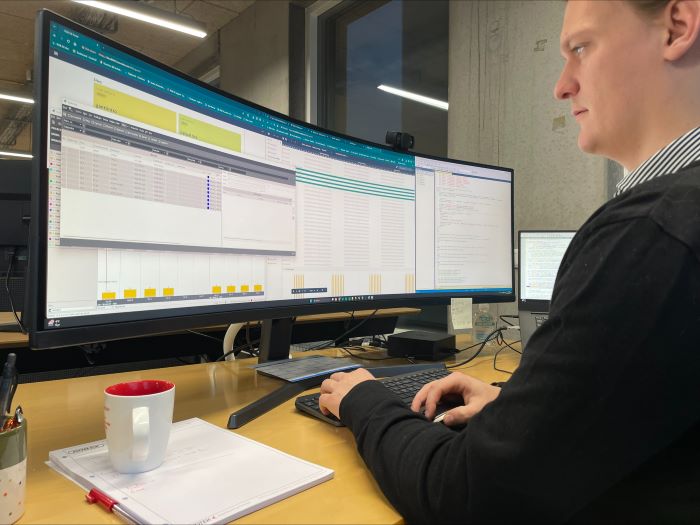

There is a lot at stake for production companies, and risks increase if they do not have the tools for maintaining a full overview of both primary and secondary consequences, when orders are rescheduled or when customers place rush orders. Daily adjustments and changes in the production plan often stresses the whole organisation, from sales over production to stocks. It is crucial that overview be maintained when changes occur, so that production operates optimally at all times. If an order is cancelled or materials are delayed, a fully visualised graphic overview is necessary to make the most efficient adjustments in production and order flow, inform customers of changes and provide reliable delivery times.

”A full overview of production makes it possible to spot bottlenecks, and to view immediate and subsequent consequences of moving orders around in the plan when unplanned changes and delays occur. Every day, we see how a fully visualised graphic and continuously updated overview saves enterprises a lot of time and money, as they are able to respond immediately and efficiently when unforeseen events occur, and they are able to act proactively when external situations change,” explains Kristian Skytt Mikkelsen.

Production scheduling is a daily challenge in many production companies. Many planners find their scheduling systems inadequate at managing the full range of complexities in modern production, and they often find that the systems ’fail to match reality’. Often planners do not have a system that provides a fully visualised graphic overview, where they can see how activities are affected by new orders, new situations or changes. This makes it impossible for planners to act proactively and leaves them struggling with putting out fires when it is too late. Scheduling can make the company vulnerable, especially if you are groping in the dark. Production scheduling can become a liability both as regards suppliers, customers and also as regards the profitability of the company as a whole.

”It is our experience that a gradual cauliflowering of production and production scheduling is the main reason that production companies contact us. Over time, production scheduling has simply grown too detailed, extensive and complex for the existing systems to cope. When production companies contact us to hear more about ROB-EX, which is our best-of-breed system dedicated to production scheduling, they often tell us that they gradually lost their overview of production, and that they simply don’t have the tools in their existing scheduling systems to restore it. The existing system is typically based on functionality and processes from other areas of company management, not production scheduling,” says Kristian Skytt Mikkelsen, and he continues:

”The times we live in today, make it even more imperative that we have the right tools for production scheduling – we simply cannot know what tomorrow brings. In later years, we’ve seen how the world can change drastically in a heartbeat. Many production companies face new challenges as they experience a decline in orders, and consequently, in production. Unfortunately, there is not much we can do about this development, but we can support production companies in increasing efficiency and flexibility with ROB-EX, so that they become more robust and agile in such situations. Changes that occur due to either internal or external events will be viewed and dealt with as variations rather than disruptions. Companies are more resilient to change, when they have all the right tools at their disposal. In relation to production scheduling, this means having a scheduling system dedicated to handling all of the variations that production is subjected to now, and may be subject to in the future,” says Kristian Skytt Mikkelsen.

Best-of-breed software: Stand strong every day – and also through crises

Variations in production are a daily occurrence, and something that best-of-breed software is specifically developed to handle. Kristian Skytt Mikkelsen explains: ”ROB-EX provides you with a visualised graphic overview that makes it possible for you to see the immediate consequences of changes, e.g. if you need to reschedule orders, or in the event of unplanned down-time on a machine. You can see how all other scheduled orders, activities and resources are affected, immediately. You’re able to adjust activities and allocation of your resources optimally in the event of a shortage of materials and you can work with correct estimates of the workload on resources, both as regards machines and operators, so that production is geared for the actual real-life situation. You will minimise the impact of unplanned interruptions in production, as you will see them simply as variations and a natural aspect of daily scheduling. Dealing proactively and efficiently with variations, instead of reacting abruptly and haphazardly to disruption, will save you a lot of time and money,” Kristian Skytt Mikkelsen explains.

All-in-one cannot beat best-of-breed in its specialised field – but it can integrate best-of-breed

”It is important for me to emphasise that ROB-EX is not, and never has been, intended as a competitor to all-in-one solutions such as ERP systems. ROB-EX is a value generating add-on that provides the visualised graphic overview that many production companies lack in their all-in-one systems. Even though we work exclusively on ROB-EX, we have comprehensive experience with ERP systems. Implementation of ROB-EX almost always involves full integration between ROB-EX and our customers’ ERP systems. Data is imported from the ERP system, processed in ROB-EX and subsequently exported back into the ERP system. We provide consultancy services in relation to the integration process, and we are often called out again when the existing ERP system is upgraded or if the company decides to change their ERP system. Our systems work together, and it seems only natural that we assist in these processes,” says Kristian Skytt Mikkelsen.

If you have only ever worked with all-in-one systems, it is really difficult to see add-ons as anything other than an extra expense. However, best-in-breed solutions are tools that also generate value and improve your bottom line. As regards production scheduling, there is absolutely no doubt that you will, as a minimum, save both time and money if you have a full and continually updated overview of production. You will often find that your overview improves efficiency (saving of money and/or increased output) and flexibility (more agile in relation to changes and improved customer relations through more reliable delivery times).

”In short, ERP systems cannot provide what ROB-EX provides. ROB-EX strengthens the scheduling function and can integrate with the ERP system to optimise production efficiency and output. ROB-EX processes data from your ERP system and from your production, and provides the tools for analysing order flow, estimating capacity, spotting bottlenecks, detecting causes for down-time on machines, optimising setups and changeovers and running selected sequences consecutively. In other words, ROB-EX provides something that all-in-one solutions cannot. We know from experience, and from customer feedback, that companies very rarely save money by running all company activities through the same system. Quite the opposite, in fact!” concludes Kristian Skytt Mikkelsen.