Scheduling: projects and capacity in a single system

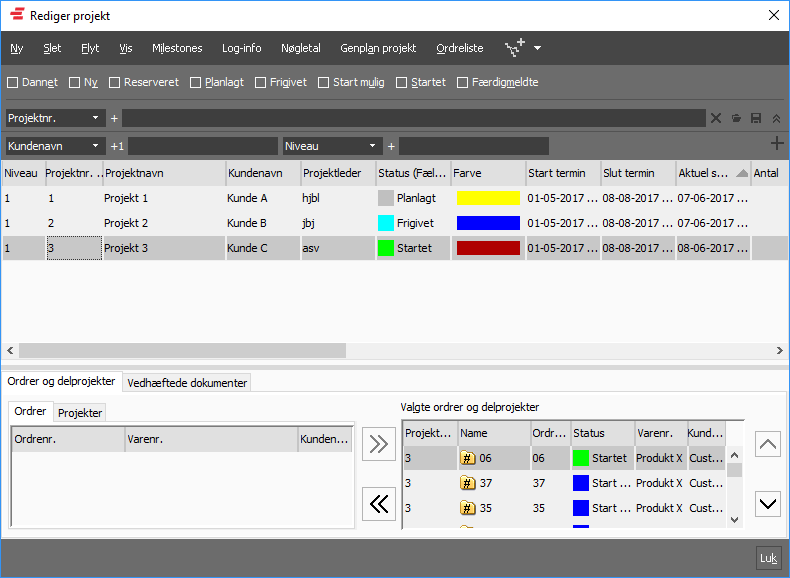

It is easy to lose your overview in large projects with many production orders. The project module in ROB-EX Scheduler makes managing projects easier.

With ROB-EX you can

- set up and schedule each project

- keep an overview of how individual projects affect your capacity

- have an overview of how your capacity is utilised by each project and by the projects combined

The project module is suited for companies that operate with project manufacturing, e.g. machine manufacturers and other manufacturing companies that produce multiple parts as sub-assemblies to be used in the finished delivery.

Your project portfolio is scheduled on resources. You are able to simulate the revenue on ongoing projects, so that you are able to compare process results with the budgetted revenue.

Simple setup of projects

If your projects have been defined in another system, you are able to import them into ROB-EX – or you can use the templates available in ROB-EX to set up both simple and highly complex projects.

Features included in ROB-EX Viewer – project:

- Project level in the activity hierarchy

- Gantt chart that provides a full overview of projects

- Project accounts that compare budgets with the scheduled activities